Search results

Search for "interfacial energy" in Full Text gives 25 result(s) in Beilstein Journal of Nanotechnology.

Density functional theory study of Au-fcc/Ge and Au-hcp/Ge interfaces

Beilstein J. Nanotechnol. 2023, 14, 1093–1105, doi:10.3762/bjnano.14.90

- effects are significant. The main aim of our study was to analyse the atomic ordering in different planar Au/Ge interfaces, characterize their energetic properties and present the accompanying changes in the electronic structure. To this end, the concepts of interfacial energy and of the work of

- provide surface energy details for gold and germanium crystals and the charge density differences for the Au/Ge heterostructures. Methodology Interfacial energy and the work of separation in DFT calculations In contrast to the bulk phase of a material, the surface atoms have an incomplete set of neighbors

- implementations [12][27]. Here we focus on the approach in which two crystalline solids (X and Y) form a supercell with imposed periodic boundary conditions, that is, there are two interfaces within the supercell. The interfacial energy γint is defined as: where EXY is the total energy of the XY heterostructure

Temperature and chemical effects on the interfacial energy between a Ga–In–Sn eutectic liquid alloy and nanoscopic asperities

Beilstein J. Nanotechnol. 2022, 13, 817–827, doi:10.3762/bjnano.13.72

- increase of the interfacial energy as a function of the temperature, which can be explained by the reactivity between SiOx and Ga and the occurrence of chemical segregation at the liquid alloy surface. Keywords: atomic force microscopy (AFM); interfacial energy; liquid alloy; Introduction Recently, room

- spectroscopy to determine the interfacial energy between eutectic Ga–In–Sn liquid alloy and single nanoscopic asperities of SiOx, Au, and PtSi in the temperature range between room temperature and 90 °C. The choice of the asperity materials was motivated by their relevance in electronics and micro

- depend on the chemistry of the asperities. Furthermore, we observe a weak increase of the interfacial energy as a function of the temperature. We discuss our results based on the reactivity between SiOx and Ga and the occurrence of chemical segregation at the liquid alloy surface. Experimental We

Analysis of catalyst surface wetting: the early stage of epitaxial germanium nanowire growth

Beilstein J. Nanotechnol. 2020, 11, 1371–1380, doi:10.3762/bjnano.11.121

- ) with respect to their free energy is examined here. The decisive factor for the theoretical considerations is the interfacial energy. In order to achieve a better understanding of the interfacial interactions, three different models for estimating the interfacial energy are presented here: (i) fully

- grow germanium nanowires on different substrates is described. Keywords: dewetting; germanium; interfacial energy; Laplace pressure; nanostructure; nanowire; Ostwald ripening; wetting layer; Introduction Wetting phenomena as well as the formation and movement of droplets are essential for numerous

- interactions (“vW model”); and a semi-empirical approach, in which R. H. Ewing's considerations towards the interfacial energy between a solid metal and its melted form were applied to study the substrate–fluid interface between different materials (“AE model”). A more detailed description of the three methods

Development of a new hybrid approach combining AFM and SEM for the nanoparticle dimensional metrology

Beilstein J. Nanotechnol. 2019, 10, 1523–1536, doi:10.3762/bjnano.10.150

- interfacial energy. Adding this force to the Hertz model described in Equation 1, as there is no other external force applied on the system, the contact radius aDMT between the NP and the substrate regarding DMT model can be determined using the relation: The whole deformation of the system δ can be then

Pure and mixed ordered monolayers of tetracyano-2,6-naphthoquinodimethane and hexathiapentacene on the Ag(100) surface

Beilstein J. Nanotechnol. 2019, 10, 1188–1199, doi:10.3762/bjnano.10.118

- transforms into a compressed structure of the point-on-line type with a by 9% smaller unit cell. Presumably, the related gain in the adsorption energy per area overcompensates the loss in interfacial energy due to the lifting of the registry of the structure with the substrate (commensurate/point-on-line

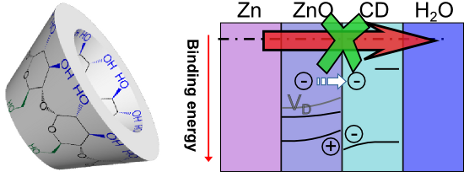

Cyclodextrin inhibits zinc corrosion by destabilizing point defect formation in the oxide layer

Beilstein J. Nanotechnol. 2018, 9, 936–944, doi:10.3762/bjnano.9.86

- interfacial energy levels of oxidized Zn was obtained from comparing the kinetic energy Ekin(jkl) of the main Auger transition jkl, here Zn LMM, with the binding energy EB(i) of a photoelectron from the main atomic level i, here Zn 2p [44][45] as The Auger parameter α is a measure in the differences in

Review: Electrostatically actuated nanobeam-based nanoelectromechanical switches – materials solutions and operational conditions

Beilstein J. Nanotechnol. 2018, 9, 271–300, doi:10.3762/bjnano.9.29

- contact area and Δγ is energy of adhesion: Δγ = γ1 + γ2 − γ12, where γ1 and γ2 are the surface energy of the contacting surfaces, and γ12 is the interfacial energy in the contact. γ12 = 0 if both surfaces are of the same material. Thus, the surface energy of the contacting materials is a critical factor

The role of ligands in coinage-metal nanoparticles for electronics

Beilstein J. Nanotechnol. 2017, 8, 2625–2639, doi:10.3762/bjnano.8.263

- authors suggest that growth was controlled by the different binding affinities of the ligands to the gold atoms (COOH < NH2 < SH) that changed the interfacial energy between core and shell, resulting in different crystal growth modes [72]. Jin et al. controlled the shape of copper nanocrystals using

Dynamic behavior of a nematic liquid crystal mixed with CoFe2O4 ferromagnetic nanoparticles in a magnetic field

Beilstein J. Nanotechnol. 2017, 8, 2467–2473, doi:10.3762/bjnano.8.246

- systems is: where K1, K2 and K3 are twist, splay and bend elastic constants, Ms is saturation magnetization, V is the particle volume, a is the average particle diameter, m is the magnetic moment of the particles, W is the surface density of the interfacial energy on the nematic boundary of the particles

Identifying the nature of surface chemical modification for directed self-assembly of block copolymers

Beilstein J. Nanotechnol. 2017, 8, 1972–1981, doi:10.3762/bjnano.8.198

- -assembly, the interfacial energy between the substrate and each block copolymer domain plays a key role on the final ordering. Here, we focus on the experimental characterization of the chemical interactions that occur at the interface built between different chemical guiding patterns and the domains of

Adsorption characteristics of Er3N@C80on W(110) and Au(111) studied via scanning tunneling microscopy and spectroscopy

Beilstein J. Nanotechnol. 2017, 8, 1127–1134, doi:10.3762/bjnano.8.114

- likely induced by a rearrangement of Au-atoms in order to reduce interfacial energy. It seems plausible that reducing the mismatch between the monolayer and the Au(111) plays a crucial role for the latter, thereby enhancing the tendency of the Er3N@C80-adlayer to grow quasi-epitaxially on the Au(111

Investigation of growth dynamics of carbon nanotubes

Beilstein J. Nanotechnol. 2017, 8, 826–856, doi:10.3762/bjnano.8.85

- metal, ΔHfusion is the latent heat of fusion, ρs and ρl are the densities of solid and liquid metal, respectively, σsl is the solid–liquid interfacial energy and σl is the surface energy of the liquid [50][51]. Figure 2 demonstrates the melting temperature of iron, nickel, gold and silver particles as a

Vapor deposition routes to conformal polymer thin films

Beilstein J. Nanotechnol. 2017, 8, 723–735, doi:10.3762/bjnano.8.76

- that only the polymer, in film form, remains on the surface. While this technique works reasonably well for flat substrates, the interaction energies between solution components coupled with its overall interfacial energy with the substrate can result either meniscus formation inside a feature (Figure

Diffusion and surface alloying of gradient nanostructured metals

Beilstein J. Nanotechnol. 2017, 8, 547–560, doi:10.3762/bjnano.8.59

- alloying processes are reviewed for various metals with a preformed GNS surface layer. We emphasize the promoted atomic diffusion and reactive diffusion in the GNS surface layer that are related to a higher interfacial energy state with respect to those in relaxed coarse-grained samples. Accordingly

When the going gets rough – studying the effect of surface roughness on the adhesive abilities of tree frogs

Beilstein J. Nanotechnol. 2016, 7, 2116–2131, doi:10.3762/bjnano.7.201

- Figure 5, we believe that our assumption is reasonable within a factor of 2. Additionally, the assumed work of adhesion may also be an overestimation since the fluid underneath the toe pad likely changes the interfacial energy. Such values, however, would also be within a factor of about 2. For example

Annealing-induced recovery of indents in thin Au(Fe) bilayer films

Beilstein J. Nanotechnol. 2016, 7, 2088–2099, doi:10.3762/bjnano.7.199

- , solid-state dewetting of thin metal films is a well-known phenomenon, which results in temperature-induced morphology changes, exposure of the substrate, and transformation of a film into an array of individual particles. This process is driven by the reduction of the total surface and interfacial

- energy of the system. Since a wide range of applications of thin metal films in the microelectronics requires featureless and defect-free surfaces, the knowledge of the effect of localized plastic strain on dewetting is of high practical importance. Surface and interface defects, such as grooves at grain

Cantilever bending based on humidity-actuated mesoporous silica/silicon bilayers

Beilstein J. Nanotechnol. 2016, 7, 637–644, doi:10.3762/bjnano.7.56

- mean radius of curvature of the pores, r, and the absolute value of the solid–liquid interfacial energy, γSL(RH), which is determined by the amount of water adsorbed during successive pore filling [13][30][38]. In addition to the solid–liquid interfacial energy, both, the curved liquid–vapor interface

- the interfacial energy of bulk silica fully wetted with water, which is known from literature (Table 1). If we make the additional assumption that the Young’s modulus of the porous silica has a quadratic dependence on its density, i.e., [34] and insert the simplified Equation 3 into Equation 2 we

Self-assembly mechanism of Ni nanowires prepared with an external magnetic field

Beilstein J. Nanotechnol. 2015, 6, 2123–2128, doi:10.3762/bjnano.6.217

- . In the third phase, Ni(II) preferentially deposits in the gaps between particles to decrease the interfacial energy, as shown in Figure 5f, which can be demonstrated by Figure 3e and Figure 3f. Comparing the diameter of the nanowires in Figure 3e and Figure 3f, it is doubtless that Ni(II) deposits on

Template-controlled mineralization: Determining film granularity and structure by surface functionality patterns

Beilstein J. Nanotechnol. 2015, 6, 1763–1768, doi:10.3762/bjnano.6.180

- these sites. The ZnO particles are attracted to these polar areas. Other particles are highly mobile due to the decreased interaction with the template. They can diffuse to the immobilized ones and decrease the interfacial energy by agglomeration. The result is a coarse granular structure that can be

Lower nanometer-scale size limit for the deformation of a metallic glass by shear transformations revealed by quantitative AFM indentation

Beilstein J. Nanotechnol. 2015, 6, 1721–1732, doi:10.3762/bjnano.6.176

- mechanisms are not activated by indentation. In the case of metallic glass, we conclude that the energy stored in the stressed volume during nanometer-scale indentation is insufficient to account for the interfacial energy of a shear band in the glassy matrix. Keywords: AFM indentation; dislocation

- resolution are higher than in any of the studies discussed above, and we still observe no serrated but only homogeneous flow. The generation of a shear band has been discussed to require the storage of a sufficient amount of elastic energy within the strained volume to overcome the interfacial energy of a

- indentation is insufficient to account for the interfacial energy of a shear band in the glassy matrix. (a) Non-contact (nc)-AFM image of an AFM-indentation on Pt(111) (z-scale: 7 nm) and highlighted masks used to determine (b) the projected area and (c) the pile-up volume of the AFM indentation shown in (a

Current–voltage characteristics of manganite–titanite perovskite junctions

Beilstein J. Nanotechnol. 2015, 6, 1467–1484, doi:10.3762/bjnano.6.152

Stiffness of sphere–plate contacts at MHz frequencies: dependence on normal load, oscillation amplitude, and ambient medium

Beilstein J. Nanotechnol. 2015, 6, 845–856, doi:10.3762/bjnano.6.87

- . We fitted the data with the JKR model. (The Tabor parameter of the geometry under study is 10, which says that the JKR model should be applied, rather than the DMT model.) Table 1 shows the derived values of the interfacial energy, γ, and the effective Young’s modulus, E. While the values are

- reasonable, they scatter quite significantly between the different experiments and the different configurations. As far as the interfacial energy, γ, is concerned, part of the problem is that the loads are rather high. A more reliable determination of γ would require more data points close to the point of

Molecular dynamics simulations of mechanical failure in polymorphic arrangements of amyloid fibrils containing structural defects

Beilstein J. Nanotechnol. 2013, 4, 429–440, doi:10.3762/bjnano.4.50

- favourable electrostatic interaction between the sheets of the three. The fact that the Class 6 polymorph is comprised of antiparallel β-sheets stacked in a parallel configuration places it intermediate between the other two. The correlation between the peak force and the electrostatic interfacial energy

- deformation. (3) If the fibrils contain a high degree of order at the interface being interrogated, and if the pulling mode applied results in a substantial separation of this interface, then the peak force required to cause mechanical failure of the fibril will be correlated with the interfacial energy. This

Surface induced self-organization of comb-like macromolecules

Beilstein J. Nanotechnol. 2011, 2, 569–584, doi:10.3762/bjnano.2.61

- preparation of heterogeneous surfaces. The proximity of macroscopic phase boundaries affects the orientation of the nanodomains as well as the film structure. Parameters, which govern the orientation, are the interfacial energy of the boundaries [121][122] and the film thickness [123]. In the case of lamellae

- micelle with outer radius and thickness a. The free energy of the micelle can be written as a sum of four contributions: The first term, Fint, is the interfacial energy: Here, and . The first term in Equation 3 is the energy of interactions of the A side chains with the substrate and the air; and are

- shell of the micelle can be written as: Here, the volume per monomer unit is assumed to be equal to the cube of the segment length. The last condition corresponds to the fact that the backbone of each particular brush molecule is almost fully stretched. Using the above conditions, the interfacial energy

Capillary origami: superhydrophobic ribbon surfaces and liquid marbles

Beilstein J. Nanotechnol. 2011, 2, 145–151, doi:10.3762/bjnano.2.18

- superhydrophobic surface [18][19]. Results and Discussion 1. Droplet wrapping theory To assess whether it is energetically favourable for a liquid to become wrapped in a solid we consider the change in interfacial energy as the solid–vapor interface is replaced by a solid–liquid interface together with the